Reconversion

with Heat2Power‑Engine [ ]

]

Reconversion with Heat2Power‑Engine

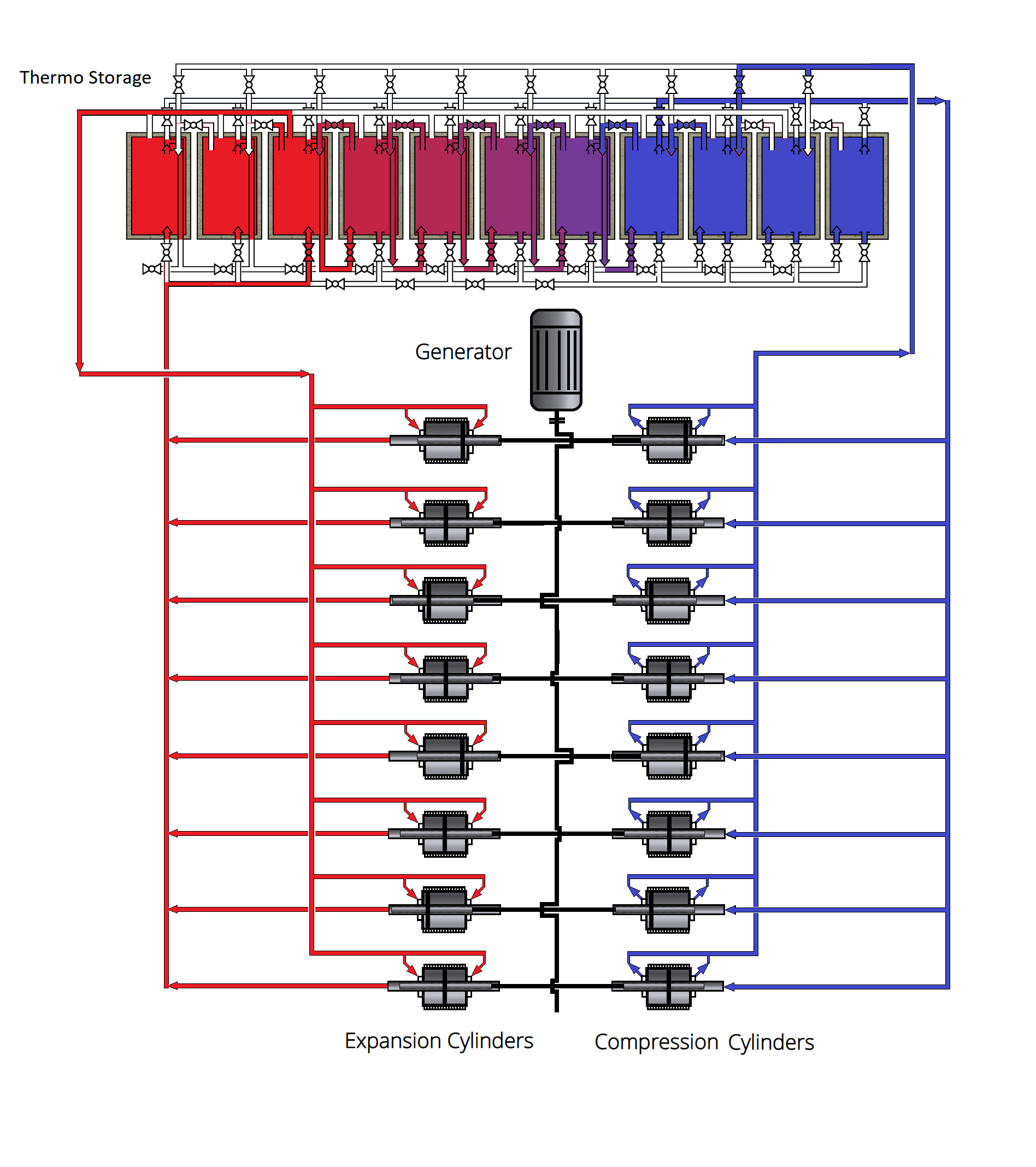

The reconversion of energy to electricity is achieved through the direct coupling of the thermal storage unit with the Heat2Power‑Engine. This unit is designed to generate electricity continuously, even with fluctuating heat input. Its modular design allows for flexible adaptation to different power requirements.Technical Implementation with Heat2Power Engine

The design of the modules (dimensions, number of parallel pipes, cross-sections, pipe lengths, flow time, temperature gradient, etc.) is designed to optimally process the heat and air volumes of the Heat2Power Engine.To overcome periods of low wind and solar power generation, the storage capacity (number of parallel storage units and number of modules per unit) can be selected to store enough energy for 4-5 days of electricity generation. Several parallel storage units – each with up to 12 modules in series – are then directly integrated into the Heat2Power-Engine circuit and function like a counterflow heat exchanger. Depending on the system design, a continuous supply of 4-6 MW of electricity can be provided. Higher outputs are conceivable.

Advantages and Integration into the Energy System

The Heat2Power Engine can be seamlessly integrated into existing energy systems. It combines power generation and heat extraction, thus creating a dual use of stored energy. Thanks to its modular design, the technology is flexibly scalable and suitable for various application scenarios.Advantages

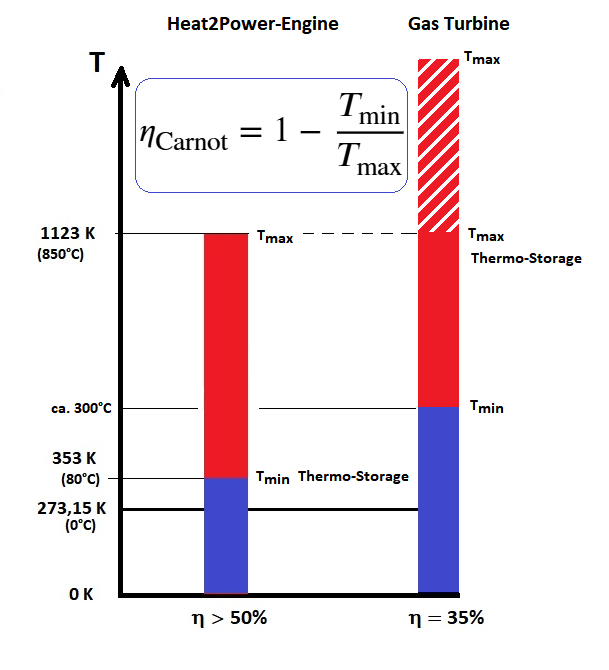

- Wide Temperature Range: The combined system of thermal storage and Heat2Power-Engine efficiently covers both high and low temperatures: The usable range is from 90 to 850°C.

- Dual Use: Power generation (90°C - approx. 850°C) and heat extraction for district heating (30°C - 90°C) operate simultaneously as needed without interfering with each other.

- Providing Low Temperatures: The configuration utilizing heat below 90°C simplifies the generation of low temperatures for the Heat2Power-Engine, thereby increasing its efficiency.

- Single Circuit: No complex circuits with different media, resulting in lower losses and reduced maintenance.

- Simplicity: The system does not require complex equipment such as filters, compressors, evaporators, condensers, etc., as is the case with other heat engine systems. The storage system and engine form an integrated circuit.

- Residual heat utilization: Excess heat from the Heat2Power-Engine process is fed back into the storage system and used for preheating.

- Continuous operation: Stable electricity production even with fluctuating heat input.

- Flexibility: If the thermal storage system is empty, the Heat2Power-Engine can also be operated with fuels if necessary.

- Modularity: Storage systems can be flexibly scaled by increasing the number of modules connected in series.

- Resource-efficient: Less battery power is needed, and no rare raw materials are required – unlike lithium batteries.

- Easy integration: Connection to existing grids/industrial plants without major modifications.

- Decentralized power supply reduces the need for grid expansion.

Deployment scenarios

- Dark doldrums: Security of supply through several days of storage capacity.

- Self-sufficiency: Electricity supply for municipalities and energy-intensive industries.

- District heating: Heat extraction for neighborhoods and cities via existing networks.

- Hybrid operation: Direct coupling with wind and PV systems to utilize surplus electricity.

Comparison with competing systems

Overview

| System type | Temperature range | Efficiency (electric) |

Second medium | Availability | Note |

|---|---|---|---|---|---|

| Steam turbine | > 300°C | 35–42 % | Steam absolutely necessary | high | Established on large scale, sluggish |

| ORC (Organic Rankine) | 80–180°C | 10–20 % | organic medium required | medium | compact, but few power |

| Classic Storage | Heat only | – | yes | high | Charging / discharging only |

| Gas turbine (Brayton) | > 800°C | 30–40 %, 15-22 % at max. 850°C |

only with additional technology | high | Only useful at very high temperatures |

| New Thermo Storage + Heat2Power-Engine | 90–850°C | 50–60% (el), >80 % total |

no, Heat optional |

very high | Electricity + heat simultaneously, modular |

That's why turbines are not suitable

Turbines are often discussed as an option for reconversion to electricity. Steam turbines are fundamentally capable of reconversion to electricity, but only indirectly via a phase change. This results in several limitations for modular storage solutions. However, gas and steam turbines are unsuitable for thermal storage solutions for several reasons:Gas Turbines:

- High temperature requirement: Conventional gas turbines require inlet temperatures exceeding 1000°C to operate efficiently. Typical storage temperatures of 500–800°C are insufficient for this.

- Secondary medium required: The gas turbine process relies on a continuous mass flow of compressed air, which is additionally heated in a combustion chamber. Direct expansion of stored air without additional fuel is thermodynamically inefficient or unstable; the overall cycle cannot be thermodynamically self-sustaining.

- Continuously high air mass flow required: Gas turbines require high, consistent mass flows. Continuous operation necessitates a constant supply of large quantities of hot air at constant pressure – technically complex and storage-intensive.

- Low load flexibility: Gas turbines are designed for stable operating conditions. With fluctuating storage capacity or partial load, efficiency drops drastically, or operation becomes unstable.

- Complex heat recovery: Targeted use of waste heat from gas turbines is only possible with additional technology and usually at a high temperature level – often unsuitable for district heating or process heat.

- Residual heat as a loss: After expansion, significant waste heat remains at a high temperature level. Without a suitable heat sink, this energy is lost unused.

Steam Turbines:

- Phase change required: The stored heat must first evaporate water. This requires additional infrastructure such as a steam generator, condenser, and water treatment system.

- Slow response time: Steam turbines are not capable of rapid start-up. They require start-up time and are unsuitable for flexible storage discharge or short-term load coverage.

- Poor part-load performance: Efficiency drops significantly at part load. This is not compatible with modular storage solutions that allow for variable discharge over several days.

- High space and maintenance requirements: The components are bulky and require intensive maintenance. Pressure vessel certification and water chemistry monitoring are mandatory.

Conclusion: Both gas and steam turbines are designed for continuous high-temperature processes with auxiliary technology. They cannot be operated modularly or directly with stored hot air. Gas turbines do not achieve a practical power density, have a significantly reduced efficiency, and there is a high risk of unstable operating conditions (on the compressor/turbine side). They are practically unusable for direct hot air expansion. Steam turbines are generally poorly suited for modular, fast-response storage systems due to their inertia, complexity, and part-load losses.

The Heat2Power-Engine avoids all these disadvantages through direct expansion of hot air – without steam, without a condenser, without delay.

Temperature profile and efficiency: Turbines vs. Heat2Power-Engine

USP of New Thermo Storage + Heat2Power-Engine-Combination

- A single circuit: No separate media, fewer losses, simpler technology.

- Simultaneous power and heat generation: Without additional components or switching.

- Modularity: Storage units can be connected in parallel; the Heat2Power-Engine remains constant.

- Counterflow principle: Multiple storage units act as a heat exchanger – higher efficiency.

- Robust against fluctuations: Storage smooths the feed-in; the Heat2Power-Engine runs continuously.

- Low temperatures possible: Process heat below 100°C can also be provided.

Economy (LCOE)

- ORC systems: 15–25 ct/kWh, highly dependent on temperature and load.

- Steam turbines: 5–10 ct/kWh, but high investment costs.

- New Thermo Storage + Heat-to-Power engine: 6–8 ct/kWh at medium load.

- Special feature: No fuel costs when using surplus electricity; heat is used in parallel.

The combination of thermal storage and Heat2Power-Engine thus offers a unique balance of technical flexibility, efficiency and cost-effectiveness – especially with volatile feed-in and simultaneous heat utilization.

Contact + License Inquiry

- Dipl. Ing. Thomas Seidenschnur

- info@heat2power.com