The new generation of industrial hot gas engines

„We cannot solve our problems with the same thinking we used when we created them.“ (A. Einstein)

]

]„We cannot solve our problems with the same thinking we used when we created them.“ (A. Einstein)

From the Stirling engine to the Heat2Power Engine – The revolution of the externally heated high-performance heat engine for utilizing industrial waste heat and power generation during periods of low wind and solar output is based on a fundamentally restructured process that differs significantly from the classic Stirling principle.

The result: High power density, excellent efficiency – based on a strikingly simple mechanical design.

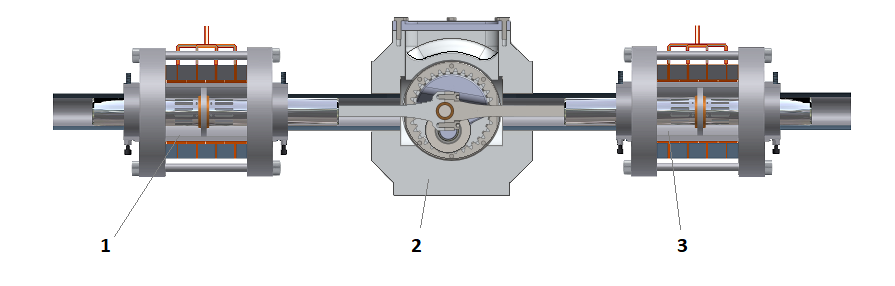

The cylinders are arranged linearly in a boxer configuration and connected by a

Hypocycloid linear guidance

![]() .

For every hot working cylinder, there exists a cold compression cylinder.

.

For every hot working cylinder, there exists a cold compression cylinder.

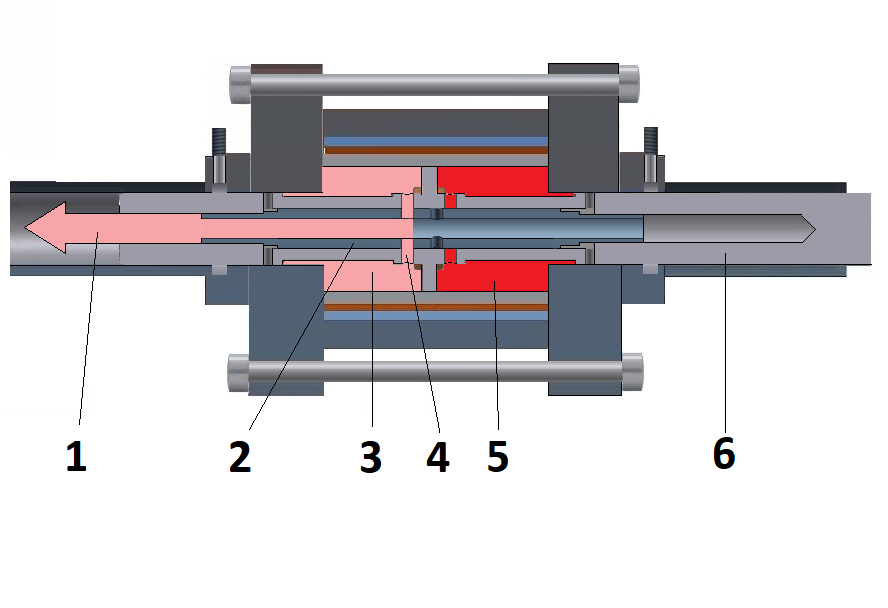

Each double-acting cylinder contains two chambers, one of which is actively connected to the piping system during the stroke – either for expansion or compression, or for emptying or filling.

The corresponding inlet and outlet channels are opened and closed by an extremely simple internal mechanism. This ensures that the flow paths are only opened or closed at defined dead centers – without external valves or complex controls.

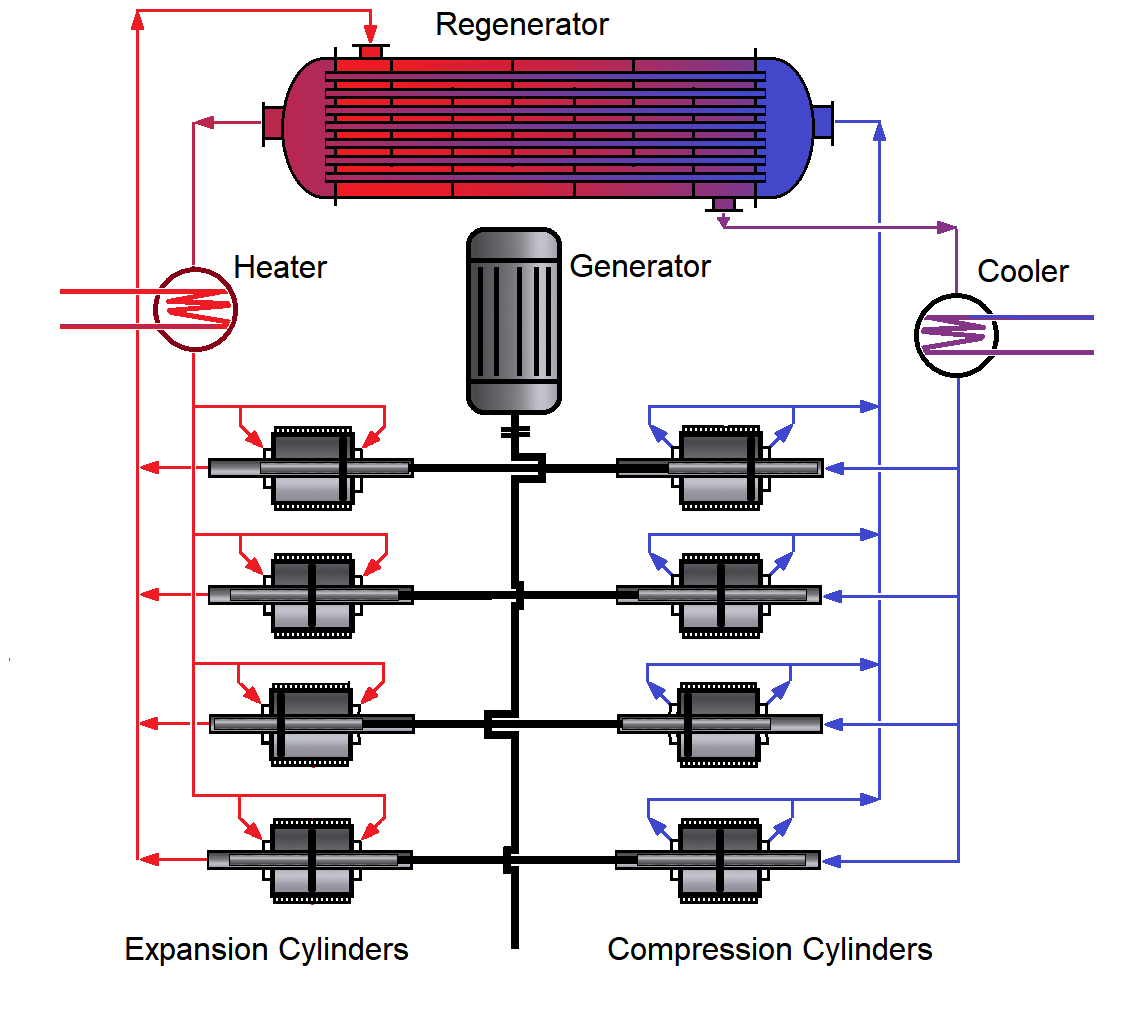

The graphic shown represents one possible implementation variant and serves to illustrate the flow guidance.

Show more technical details

1 = Expelling gas, 2 = Control piston in left end position, 3 = Expanded gas (here: in left cylinder chamber), 4 = Open exhaust port, 5 = Expanding gas (here: in right cylinder chamber), 6 = Piston rod

The Heat2Power Engine utilizes a central regenerator for heat recovery – designed as a counterflow tube bundle heat exchanger with a permanently stable temperature distribution. The cyclically offset gas flow enables continuous regeneration without feedback losses.

Heat2Power-Engine - System showing the flow paths

The switching of the flow paths between the cylinder chambers and the piping system is achieved by an internal mechanism that is automatically activated at the dead centers. One chamber opens while the other remains closed – synchronized with the piston movement.

Several design principles are available, including

In principle, this is the implementation of a pulse tube cooler integrated with the compression cylinder.

FAQ - Pressure-controlled switching

[Answer] It must be ensured that no further gas flows in after the expansion process has started.

The switching of flow paths can also be achieved through a purely mechanical solution within the piston rod. In this case, the flow connection between the cylinder chamber and the pipe system is activated at defined dead points by internal moving elements..

The animation shown illustrates one possible variant with mechanically controlled rotary motion. Further versions – including pneumatically or magnetically assisted versions – are conceptually developed.

The Heat2Power-Engine is powered by a central heat source. Depending on the application, various configurations are possible:

The Heat2Power-Engine is predestined for high performance – and delivers it without compromise:

| Losses | internal combustion engine | Heat2Power Engine |

| Friction losses | up to 15 % | up to 5 % |

| Cooling losses | up to 25 % | up to 10 % |

| Exhaust gas losses | up to 35 % | 0 ... 10 % |

| Radiation, wall heat losses | up to 15 % | up to 10 % |

| Combustion losses, charge exchange, purging losses, imperfect thermodynamic process |

up to 40 % | up to 15 % |

| Total: | apr. 65 % (Experience) | apr. 35 … 50 % |

| Residual efficiency (1 – Total) | apr. 35 % (Experience) | apr.. 50 … 65 % |

The Heat2Power Engine systematically reduces all major sources of loss in conventional engines – through low-friction mechanics, the absence of combustion and exhaust gas, complete regeneration, and flow-optimized cycle management. The resulting residual efficiency of 60–65 % is not theoretical, but rather demonstrably achievable and computationally verifiable in conjunction with a suitable temperature range.

How are the favorable values achieved with Heat2Power Technology? Read more about the obvious and undeniable...