Submarines

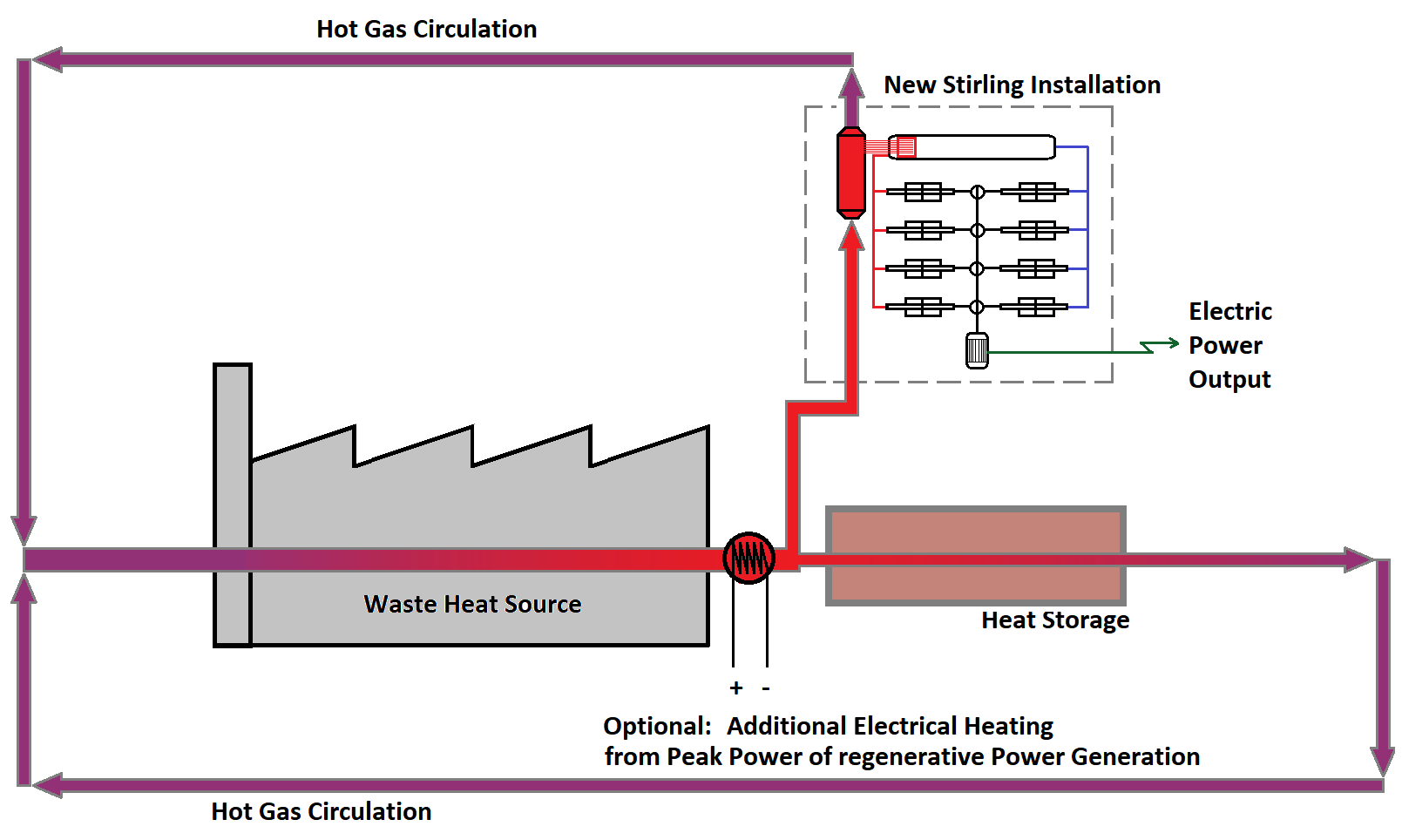

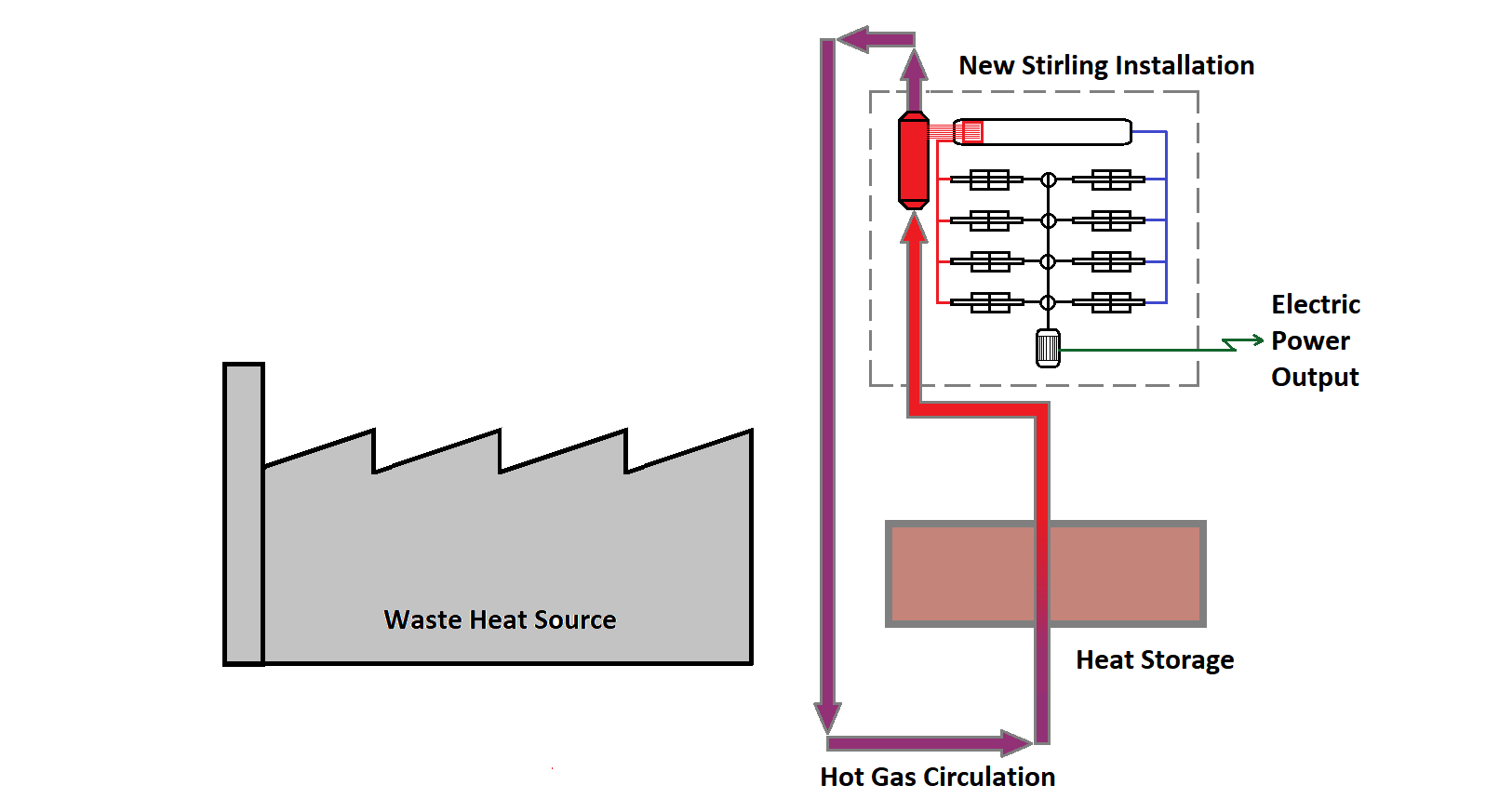

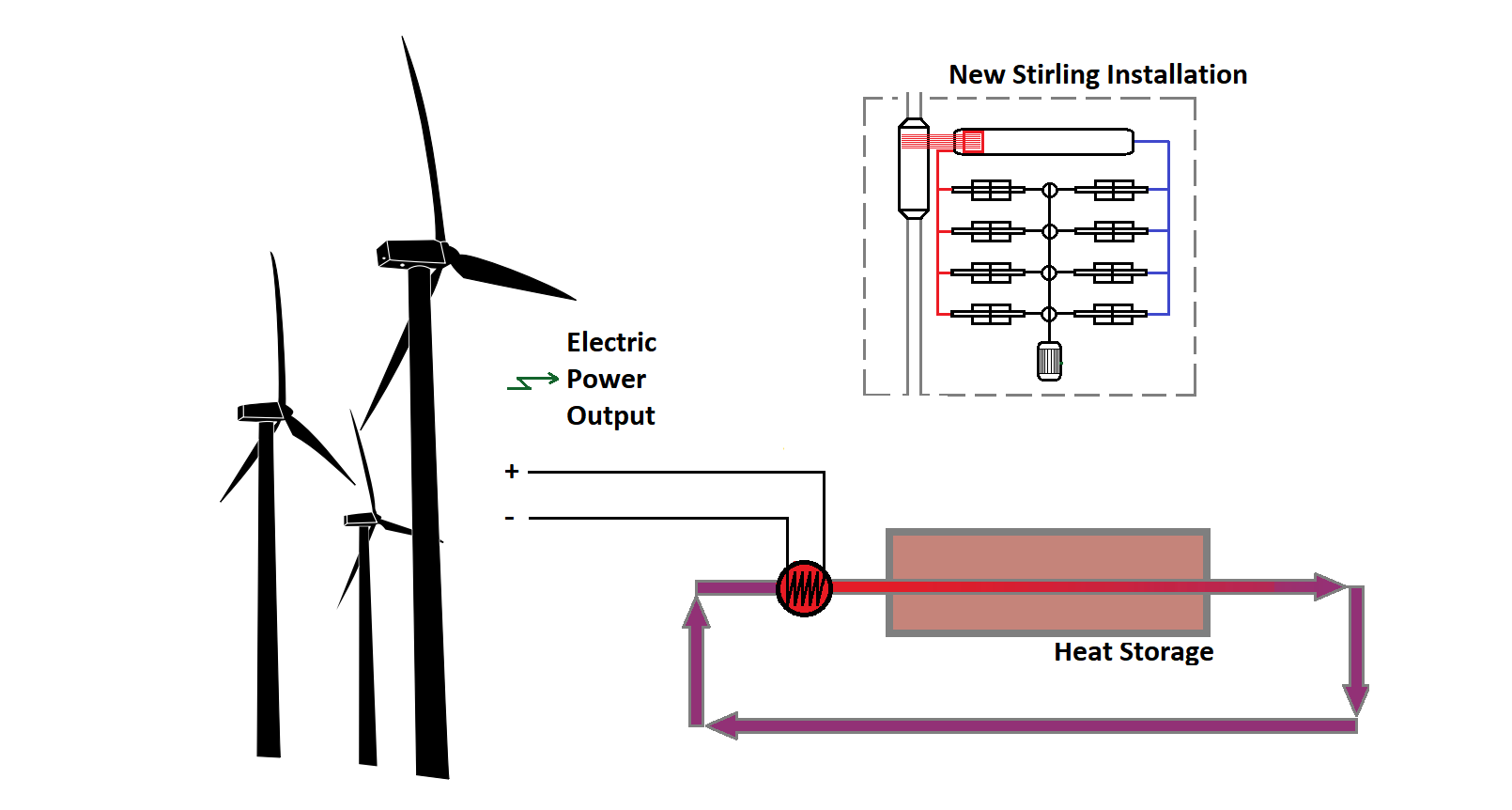

The Heat2Power-Engine opens up entirely new possibilities for submarine propulsion:

It replaces conventional diesel and AIP systems with a single, efficient solution, increasing range, efficiency, and stealth.

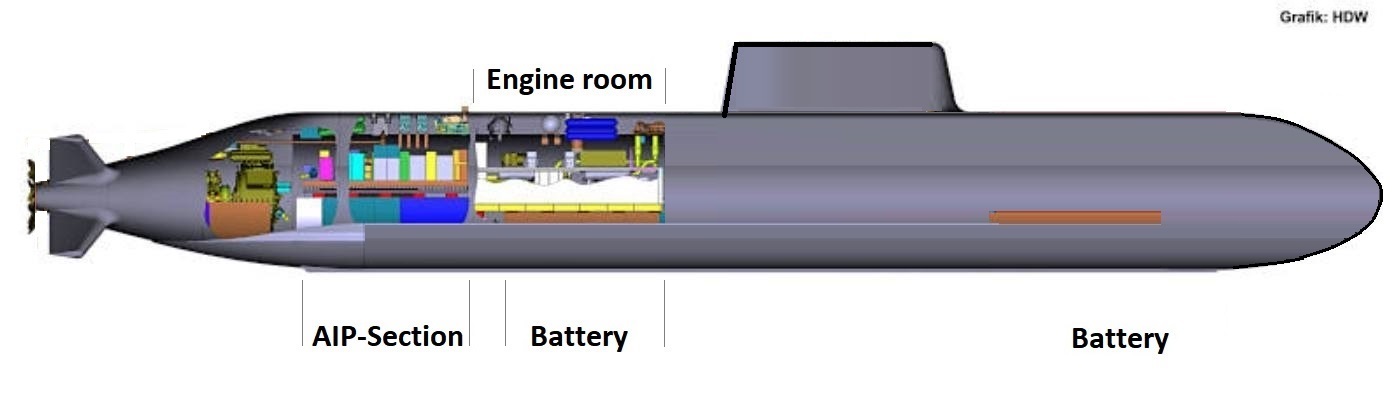

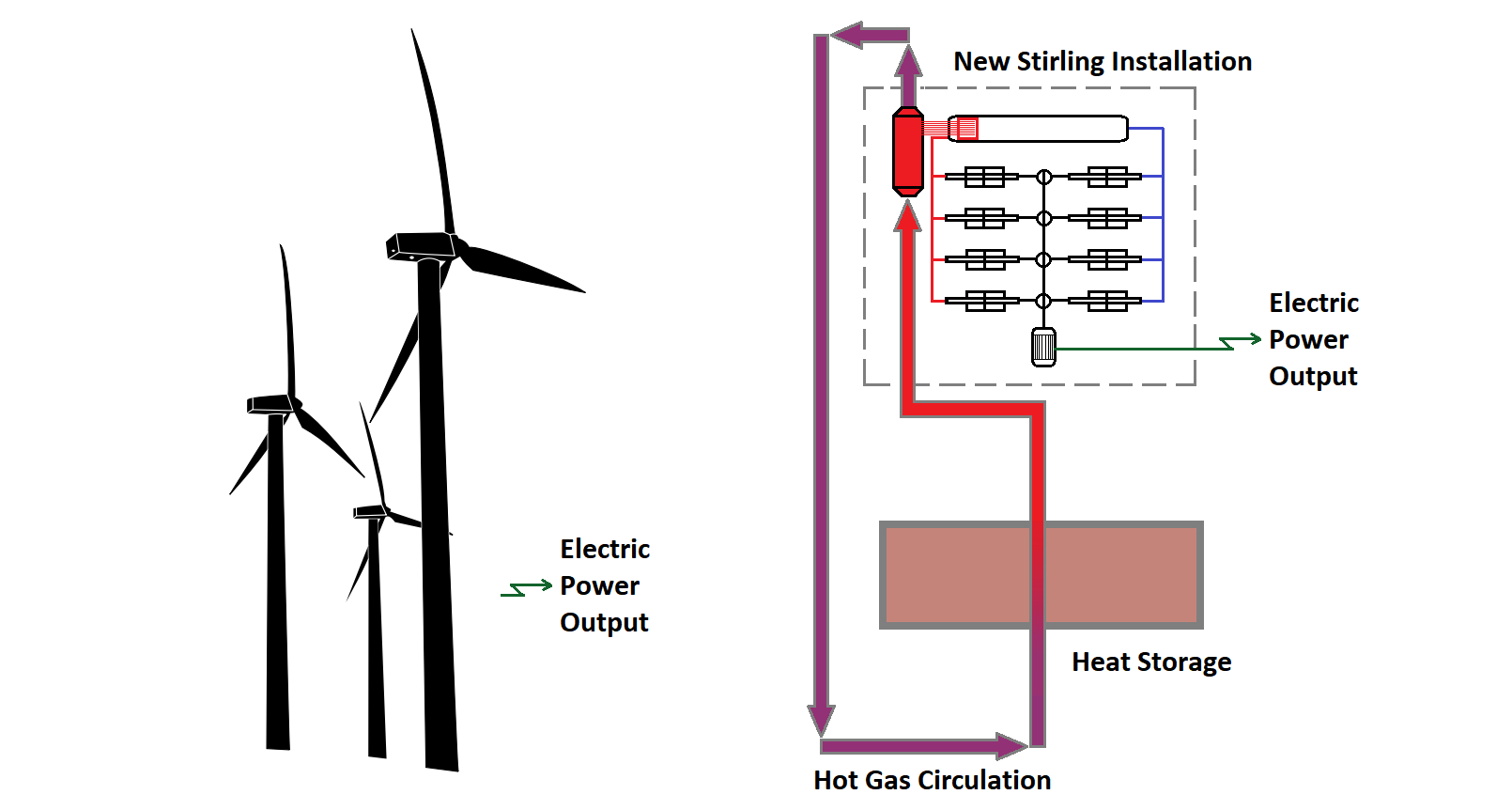

- Previous Technology: Conventional submarines use two systems – diesel for surface travel and AIP (usually fuel cells or Stirling engines) for submerged travel.

- Limitations: AIP delivers only a few hundred kW, sufficient for extended underwater stays, but not for long ranges at cruising speed.

- Solution: A single Heat2Power engine replaces both systems and enables full power both above and below the surface.

- Oxygen Supply: 1 kg of diesel requires 0.58 kg of O2; 1000 liters of diesel require only 1.0 m³ of O₂ at 335 bar – technically easy to achieve.

- Cooling & Efficiency: The expansion of the compressed O₂ produces a significant temperature drop, which is used for cooling and increasing efficiency while simultaneously reducing the heat signature.

- Advantages: Long range, less complexity, silent operation, high efficiency, and smaller footprint.

- Conclusion: The Heat2Power engine makes nuclear submarines obsolete.

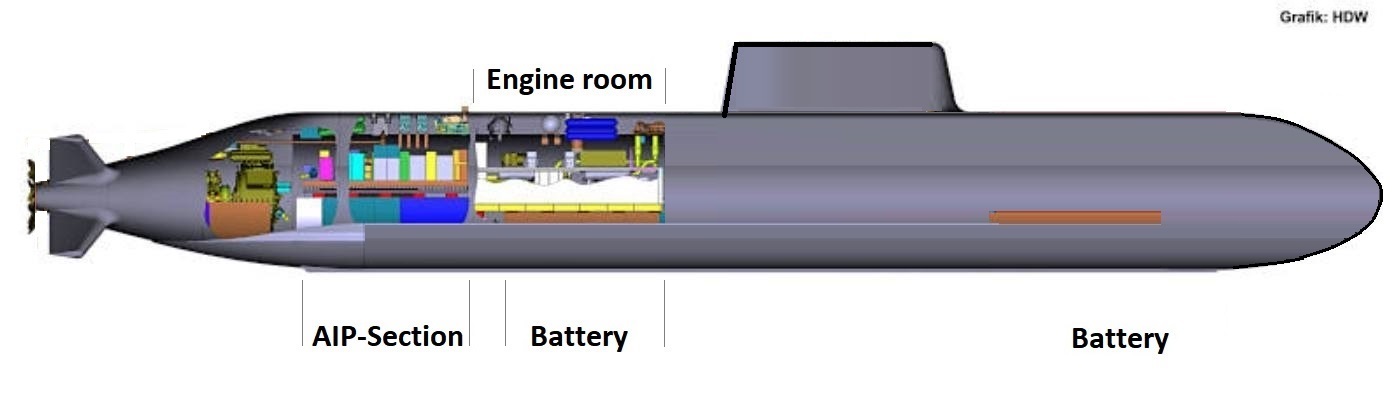

Typical design of modern conventional submarines. Here: HDW's U-216 concept with fuel cell AIP.

]

]