Continous Step Burning (COSTAIR)

Basics

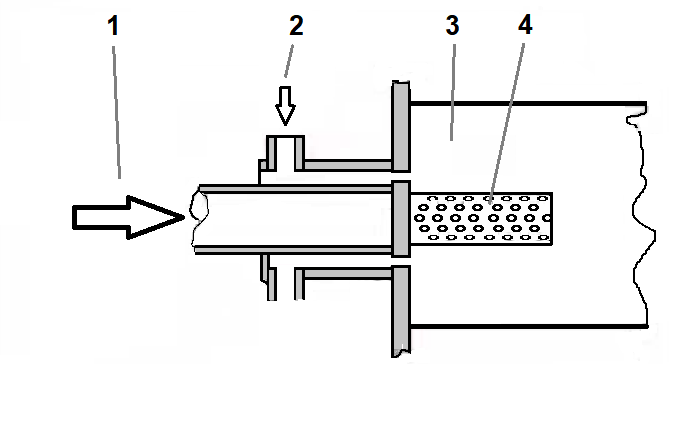

The COSTAIR (COntiniusly STaged Air with Internal Recirculation) principle follows the approach of continuous air grading. With the COSTAIR gas burner, the continuous supply of combustion air inside the flame acts on the development of pollutants.The gas and combustion air mix injected at high speed via the injector burner head mixes in the combustion chamber with internally recirculated hot exhaust gas, the combustion is virtually flameless.

The main feature of the COSTAIR burner is the air diffuser. Through this air distributor, the air is injected through a large number of openings into the reaction zone, so that there is continuous air gradation.

The fuel gas nozzles are arranged around the air distributor on a circular ring.

A recirculation area is formed behind the air distributor, as a result of which exhaust gas flows into the reaction zone and thus the fuel-air mixture is diluted. By air staging and recirculation of the hot exhaust gases, the temperature is evened out and the O2 partial pressure is reduced, which in turn cause a reduction in NOx emissions.

By modifying the air distributor geometry (e.g. number and arrangement of the air holes, changes to diameter and length of the air distributor), this burner type can be optimized for different applications and the combustion chamber geometry can be adapted.

The material of the hot parts (nozzles, flanges, housing, etc.) consists entirely of stainless steel 1.4841. The burner housing is completely lined with chamotte.

1 = Air, 2 = Burning gas, 3 = Combustion chamber, 4 = Air distributor

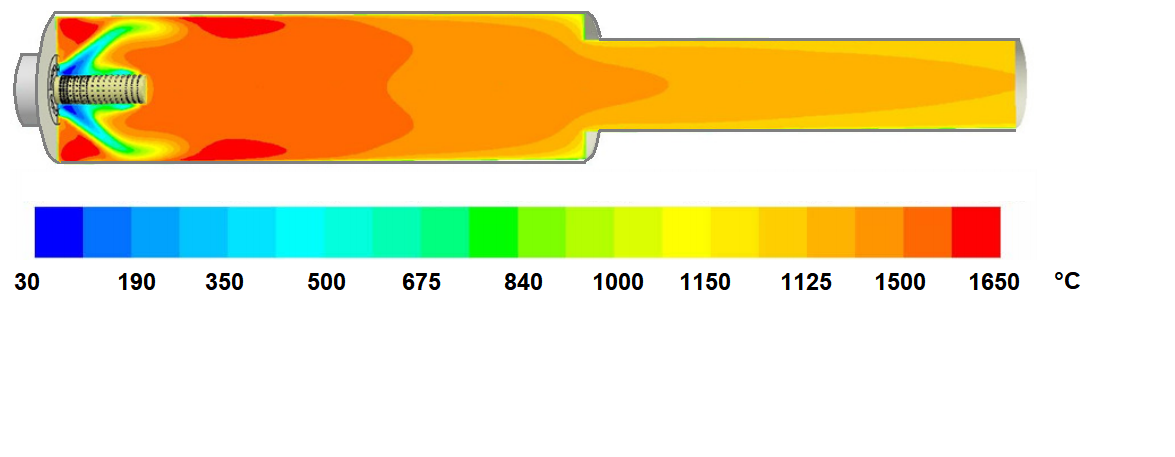

Temperature profile inside a COSTAIR Burner

Advantages

- Only low levels of nitrogen oxides are produced during combustion

- The carbon monoxide values also tend towards zero

- Another advantage of the new gas burner results from the shape of the flame, which spreads closer to the wall of the boiler combustion chamber and improves heat transfer

[Click elsewhere on the background of the main window to close this popup]